Ngaphambi kokwakhiwa,umkhondo wokubaleka werabha owenziweyos zifuna umgangatho othile wokuqina komhlaba, ukuhlangabezana nemigangatho yobulukhuni phambi kokuba kuqhutyekwe nokwakhiwa. Ke ngoko, isiseko sesiseko seendlela zokubaleka zerabha esenziwe ngaphambili kufuneka ziqiniswe.

Isiseko esiKhonkrithi

1. Emva kokugqitywa kwesiseko, umphezulu we-samente awufanele ube mde kakhulu, kwaye akufanele kubekho iziganeko ezifana ne-sanding, i-peeling, okanye i-crack.

2. Ukuma okuthe tyaba: Ireyithi yokupasa xa iyonke kufuneka ibe ngaphezulu kwe-95%, kunye nokunyamezelana okungaphakathi kwe-3mm kumgama othe ngqo we-3m.

3. Ukuthambeka: Kufuneka kuhlangabezene nemigaqo yobugcisa bezemidlalo (ithambeka elisecaleni lingabi likhulu kune-1%, ithambeka le-longitudinal elingekho ngaphezulu kwe-0.1%).

4. Amandla acinezelayo: R20 > 25 kg/square centimeter, R50 > 10 kg/square centimeter.

5. Umphezulu wesiseko kufuneka ukhululeke ekuthinteleni kwamanzi.

6. Ukuxinana: Ukuxinana komphezulu kufuneka kube ngaphezu kwe-97%.

7. Ixesha lokugcinwa: Ngaphezu kwe-25 ° C iqondo lokushisa ngaphandle kweentsuku ezingama-24; phakathi kwe-15°C kunye ne-25°C ubushushu bangaphandle kangangeentsuku ezingama-30; ngaphantsi kwe-25 ° C ubushushu bangaphandle kwiintsuku ezingama-60 (ukunkcenkceshela rhoqo ngexesha lokugcinwa ukususa amacandelo e-alkaline kwisamente eguquguqukayo).

8. Izigqubuthelo zomsele kufuneka zihambe kakuhle kwaye ziguquke ngokufanelekileyo kunye nomzila ngaphandle kwamanyathelo.

9. Ngaphambi kokubeka iingoma zerubha ezenziwe ngaphambili, isiseko sesiseko kufuneka singabi neoli, umlotha, kwaye some.

Isiseko se-asphalt

1. Umphezulu wesiseko kufuneka ungabikho kwiintanda, iimpawu ezicacileyo ze-roller, amabala e-oyile, amaqhekeza e-asphalt angaxutywanga, ukuqina, ukucwiliswa, ukuqhekeka, ubusi, okanye ukuxobula.

2. Umphezulu wesiseko kufuneka ukhululeke ekuthinteleni kwamanzi.

3. Ukuthe tyaba: Ireyithi yokupasa ngokutyaba kufuneka ibe ngaphezulu kwe-95%, kunye nokunyamezelana okungaphakathi kwe-3mm phezu kwe-3m eqondileyo.

4. I-Slope: Kufuneka ihlangabezane nemigaqo yobugcisa bezemidlalo (i-slope esecaleni ingabi ngaphezu kwe-1%, i-longitudinal slope ayikho ngaphezu kwe-0.1%).

5. Amandla acinezelayo: R20 > 25 kg/square centimeter, R50 > 10 kg/square centimeter.

6. Ukuxinwa: Ubuninzi bobunzima bomphezulu kufuneka bube ngaphezu kwe-97%, kunye nomthamo owomileyo ufikelela ngaphezu kwe-2.35 kg / ilitha.

7. Indawo yokuthambisa i-asphalt> 50°C, ubude ngama-60 cm, ubunzulu bokungena kwenaliti 1/10 mm> 60.

8. I-Asphalt thermal stability coefficient: Kt = R20 / R50 ≤ 3.5.

9. Ireyithi yokwandisa umthamo: <1%.

10. Izinga lokufunxa amanzi: 6-10%.

11. Ixesha lokugcinwa: Ngaphezu kwe-25 ° C iqondo lokushisa ngaphandle kweentsuku ezingama-24; phakathi kwe-15°C kunye ne-25°C ubushushu bangaphandle kangangeentsuku ezingama-30; ngaphantsi kwe-25 ° C ubushushu bangaphandle kwiintsuku ezingama-60 (ngokusekelwe kumalungu aguquguqukayo kwi-asphalt).

12. Izigqubuthelo zomsele kufuneka zihambe kakuhle kwaye ziguquke ngokufanelekileyo kunye nomzila ngaphandle kwamanyathelo.

13. Ngaphambi kokubeka iindlela zokugijima zerabha ezenziwe ngaphambili, coca umgangatho wesiseko ngamanzi; umaleko wesiseko kufuneka ungabi naoli, umlotha, kwaye wome.

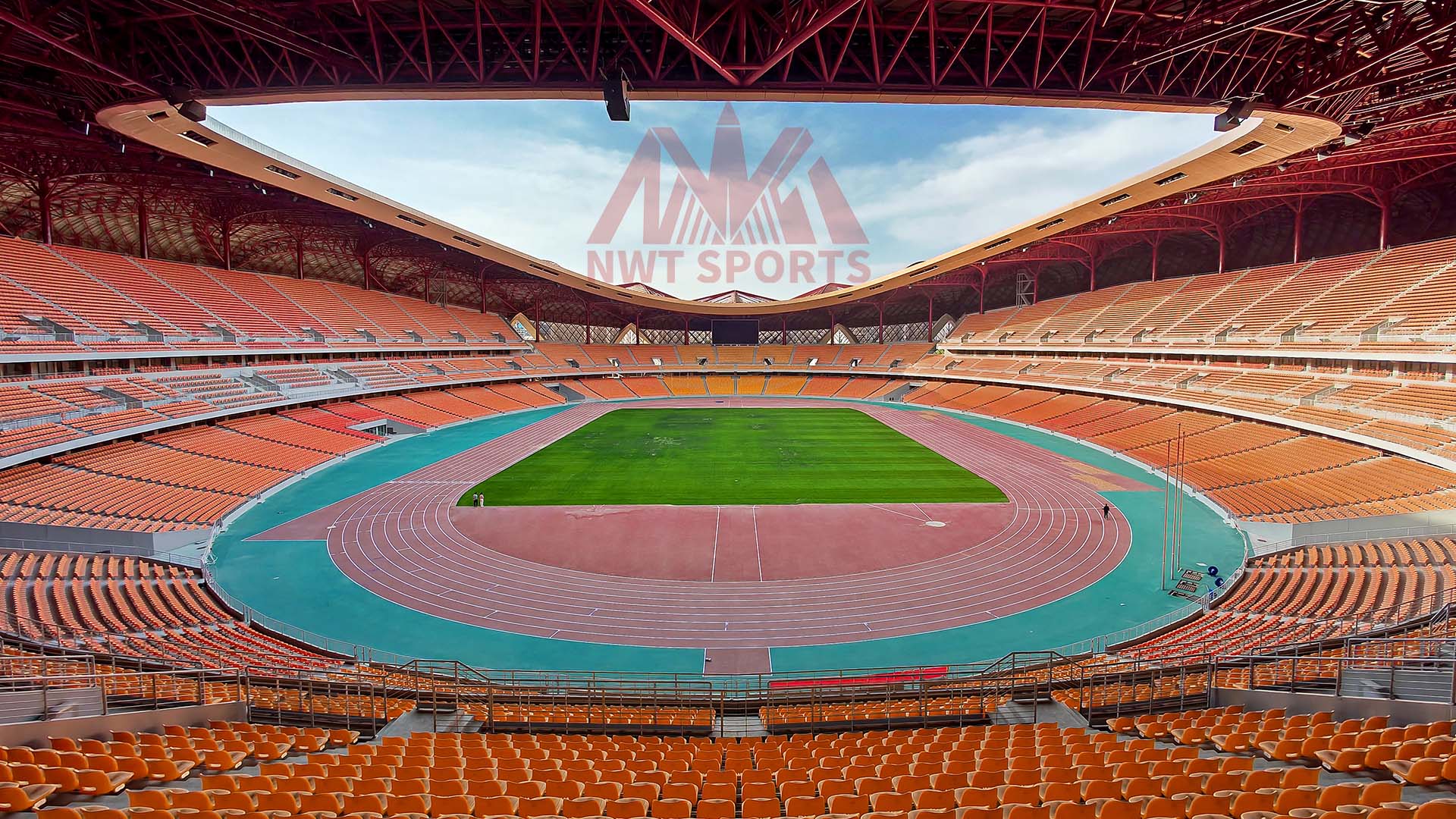

Isicelo seTrack yokuBaleka yerabha eseyakhiwe ngaphambili

IiParameters zoMkhondo weRubber owenziweyo

| Iinkcukacha | Ubungakanani |

| Ubude | 19 yeemitha |

| Ububanzi | 1.22-1.27 imitha |

| Ukutyeba | 8 mm - 20 mm |

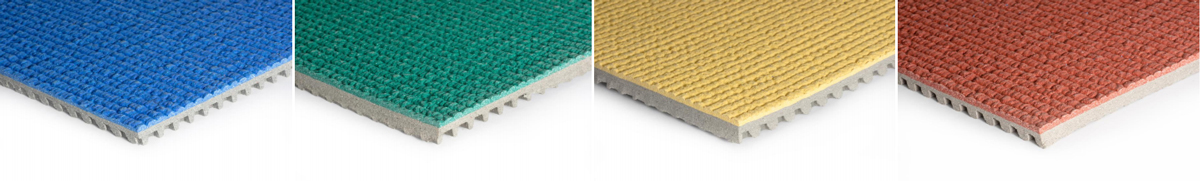

| Umbala: Nceda ubhekisele kwikhadi lombala. Umbala okhethekileyo nawo unokuxoxisana. | |

Ikhadi leMbala leMbala leRabha eSetyenzisiweyo

IiNkcukacha zoMkhondo woMbaleko weRubber eSetyenzisiweyo

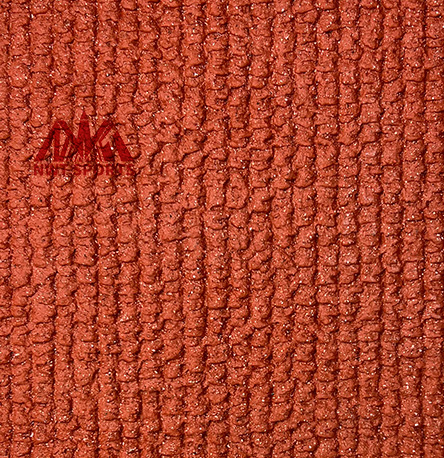

Umaleko onganxibiyo

Ukutyeba: 4mm ±1mm

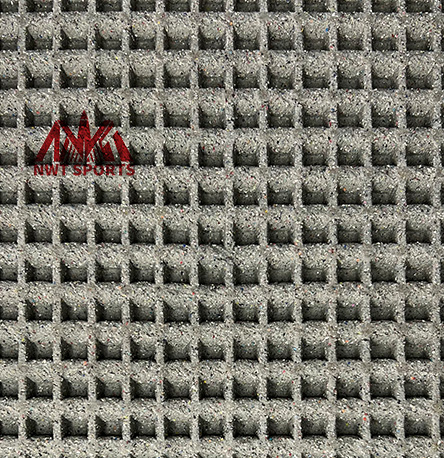

Ulwakhiwo lwengxowa yomoya yobusi

Malunga nama-8400 emingxuma kwisikwere semitha

Umaleko wesiseko se-elastic

Ukutyeba: 9mm ±1mm

UFakelo lweTrack yeRubber eSetyenzisiweyo

Ixesha lokuposa: Jun-26-2024